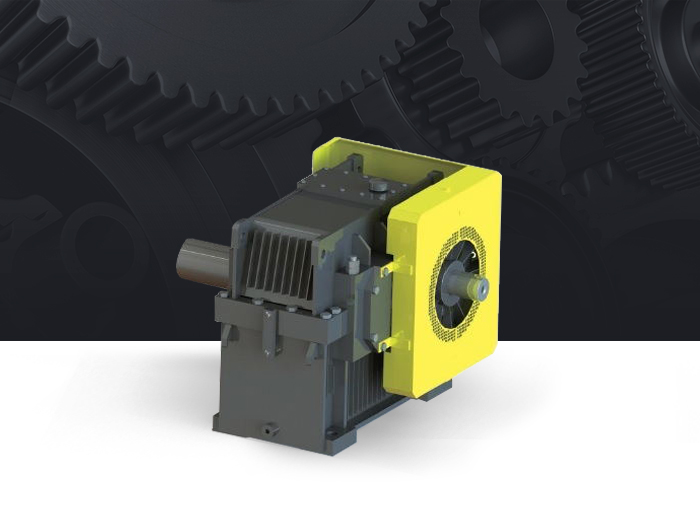

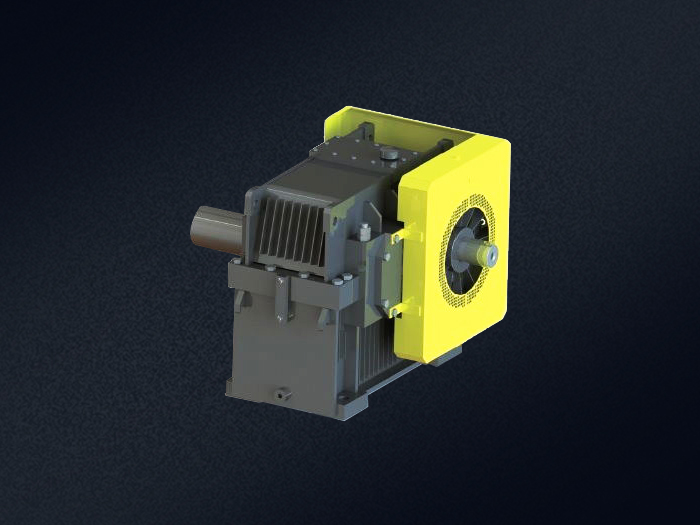

This series is developed specifically for the characteristics of domestic underground coal mines, it features high reliability, easy maintenance, and high efficiency and energy saving.

ConsultingApplication Area: Metallurgical Mining

Product features: Reliable operation; highly modular design; tooth surface modification to improve load-bearing capacity and noise reduction performance.