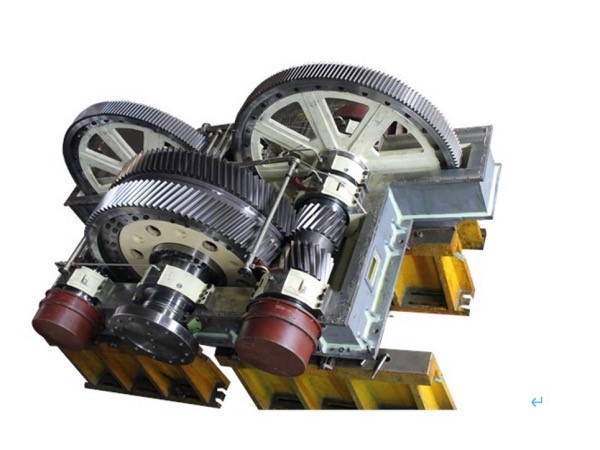

The JK series is a bevel cylindrical gear transmission device with 2, 3, and 4 stages of reduction, and the input shaft is perpendicular to the output shaft. The cylindrical gears are designed as helical gears, while the bevel gears are spiral bevel gears. All gears are made of advanced alloy steel, carburized and quenched before gear grinding.

ConsultingApplication Area: metallurgy, building materials, chemical industry, mining, petroleum, transportation, papermaking, rubber and plastic, engineering machinery

Product features: high precision, high load-bearing capacity, stable performance.

This series of gearboxes features central transmission, pow..

+

This series of products adopts a three-stage planetary gear..

+

This series gearbox comply with the JB/T8853-1999 standard...

+

The JD-JDX series reducer is a single-stage reduction devic..

+