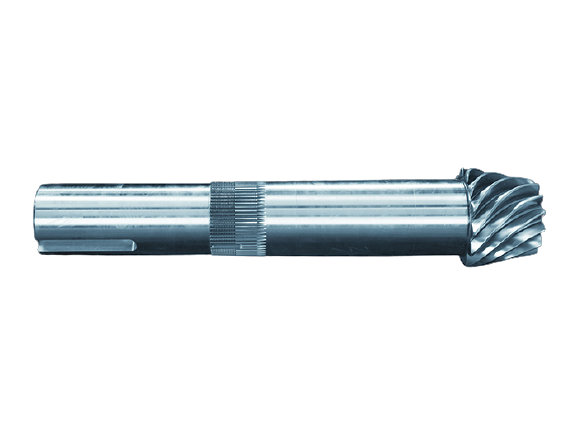

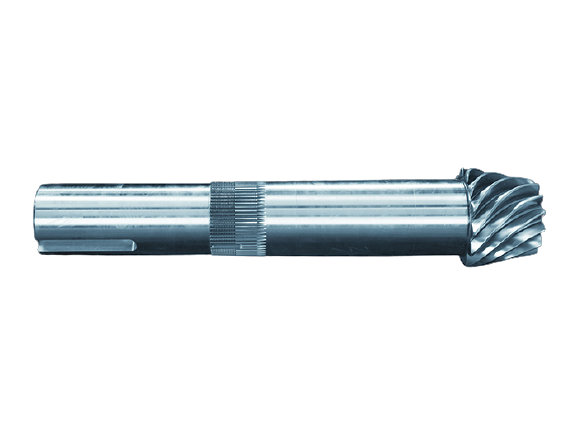

It is an involute gear with no back cut groove, its module is 28mm, helix angle is 27°, tooth width is 400mm.

ConsultingApplication Area: Coal Mining

Product features: 1. Involute teeth, small or no back cutter groove, outer diameter of gear ring 2m, total length of gear shaft unrestricted, module unrestricted, tooth width 1.3m, tooth surface hardness HRC58-62, precision 5-GB10095; 2. Spiral bevel gear type: Klingelnberg and Gleason, outer diameter of large gear 2m, total length of gear shaft unrestricted, module unrestricted, can optimize the gear to improve bending and contact strength, tooth surface hardness: HRC58-62, precision: 5-DIN3965.

This gear is supplied for a research unit, its outer diamet..

+

the gear shaft is 2.5 meters long with a module of 26mm.

+

Providing processing support for a well-known domestic wind..

+

It is an exported product, the gear diameter is 1.611m, wit..

+